System Risk Assessment and Optimization

Mitigate Risk and Optimize Solutions

To give our customers and their OEMs peace of mind, we offer a proactive service tailored to mitigate risk and optimize performance of the Insequence system. Our specialists perform a thorough investigation,going over all the details our customers don’t have time for.

Perform at your best

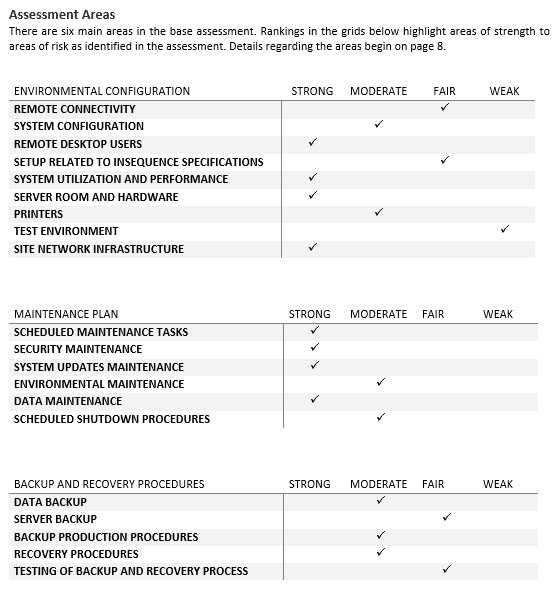

Because Insequence software is the heart of our customer’s sequential manufacturing process, our commitment is to provide software that performs at the highest, optimized levels with no risk to operations. To reinforce that commitment, we offer a detailed Risk Assessment service, designed to help increase up-time and mitigate operational risk. This proactive program consists of an intensive review of Insequence software, customer processes, customer hardware and data maintenance. Our assessment specialists identify potential areas of risk, areas of opportunity for system performance improvement and ways to optimize performance of their Insequence software, within both the solution itself and their operations. We then provide a comprehensive report on findings, complete with critical and non-critical recommendations to improve overall system functionality.

This service can help improve sequencing efficiency, decrease overall operation risk, and minimize potential penalties. Giving the OEM peace of mind for on-time and on-budget parts delivery. The service includes: System and Database Maintenance Review, Site Process Efficiency Review, Redundancy, DB Backups, System Crisis Plan, Administrator and Operator Proficiency Review, Audit Report, and Recommendations.

-

Assessment of production system

-

Findings report including optimization suggestions

-

Facility mitigates risks, optimizing operations

A Case Study: Midwest supplier, 10 sequencing stations

Challenges

- Improve operational efficiency and mitigate risk

- Enhance operations on current lines

- Prepare for site expansion with new lines added

- Staff turnover/new staff

- Recent server rebuild

Findings

- Identified four critical risk areas and 16 high impact areas

- Identified five opportunities for system optimization

- Discovered system proficiency and knowledge gaps

Results

- Immediately corrected critical risk factors, averting potential downtime during startup.

- Implemented corrective action plan to remediate areas of operational risks

- Provided system optimization recommendations for greater efficiency

- Improved system knowledge and proficiency by staff through targeted training.