Just in Sequence (JIS) Manufacturing Software

Sequencing is Believing: See What Our Complete Just in Sequence Solution Has To Offer

Used in hundreds of facilities throughout the Americas and Europe, our SPD Pro sequencing module for manufacturers and supply chain providers has proven to be a customer favorite. Consisting of multiple independent applications, it is a complete stand-alone solution for just in sequence (JIS) manufacturing. Easily tailored to your facility, regardless of complexity, SPD Pro provides you with the flexibility and stability required for successful sequencing operations.

With standard OEM communication interfaces, our Sequential Parts Delivery (SPD) Pro module oversees the entirety of a sequencing process from broadcast verification to final shipping stages, making your system more reliable and efficient from start to finish.

Let’s TalkA Leader in Automotive Sequencing

Insequence has created standard interfaces for numerous automotive OEMs such as Ford, Chrysler, GM, Toyota, Nissan, and BMW among others. Additionally, Insequence has gained experience with multiple vehicle sequencing types including ILVS, SPAB, GePICS, GALC, and MPAB.

Need a testing environment? We have you covered! With each Insequence system, customers receive licensing for a duplicate system in a non-production test environment. This gives our customers the flexibility to test new features, configurations, and workstations without impacting their operations.

All The Building Blocks You Need in A Sequencing Solution

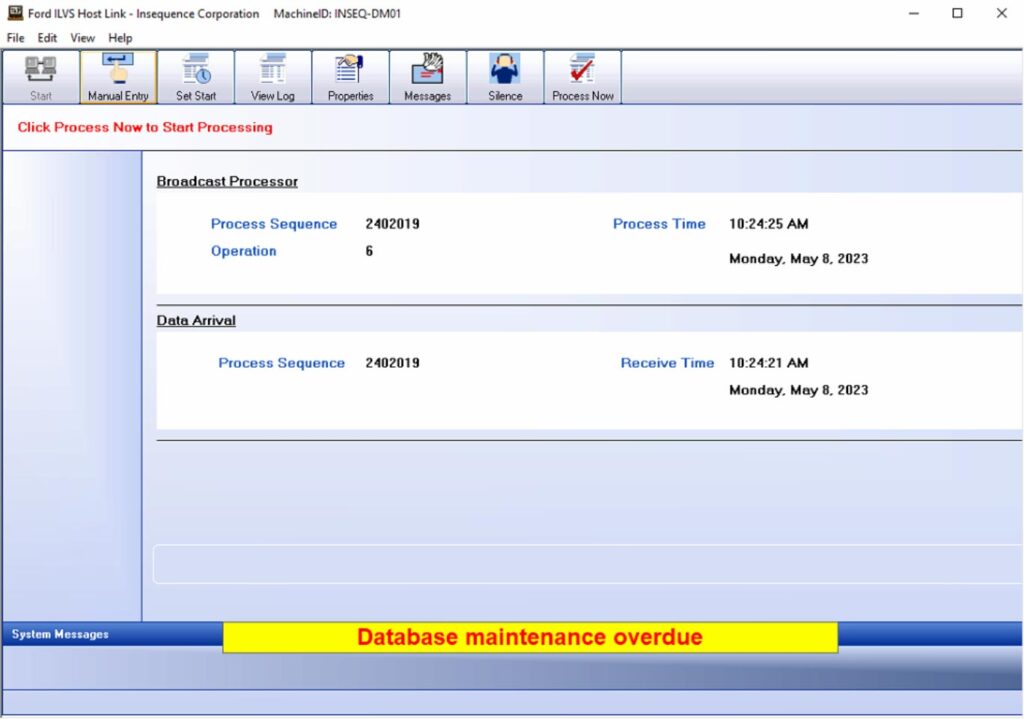

Host: Receipt, processing, and validation of OEM demand

The SPD Pro Host application performs two primary jobs: receiving and processing OEM demand. In order to receive this data, the Host first establishes and maintains a stable connection with the desired OEM. This information is then verified for accuracy and translated into a format that is standard to the rest of the SPD Pro system. Next, the Load Management application collects this information and organizes the data into rack loads. Because each OEM has their own unique way of communicating their sequencing demand, Insequence creates a standard Host for each OEM demand type SPD Pro has to process. However, all Host applications include the following essential functionality.

- See demand arrive and process

- See any associated system messages from receipt of the demand

- A log of all raw demand data is available to view

- Enter data manually

- Make substitutions for the demand

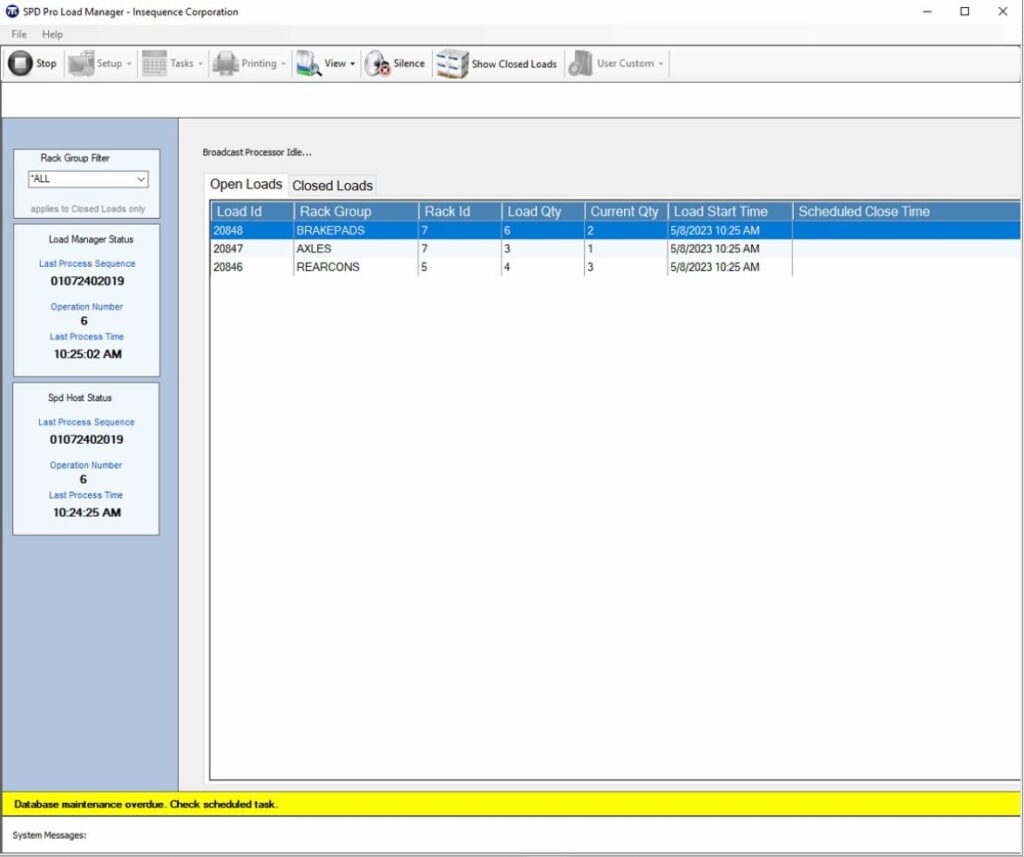

Load Manager: Vehicle sequencing information into virtual loads or racks

Receiving information from the Host, the load management application organizes the OEM demand into “virtual” racks or containers. Since sequencing relies on traceability, each load is assigned, a unique, non-repeating ID number. Load Manager then instantly creates queues based on predefined requirements. These queues are then made available to the rack loading application. Once accessible to the appropriate workstations, operators may begin picking or manufacturing. Load Manager also handles tasks such as:

- Directs printing

- Determines rack and trailer loading patterns

- Manages exports to 3rd party systems

- Allows timed load closing

- Allows timed rack shipping

- Provides a method to edit part data if there is a part back order, part replacement, or part cancellation

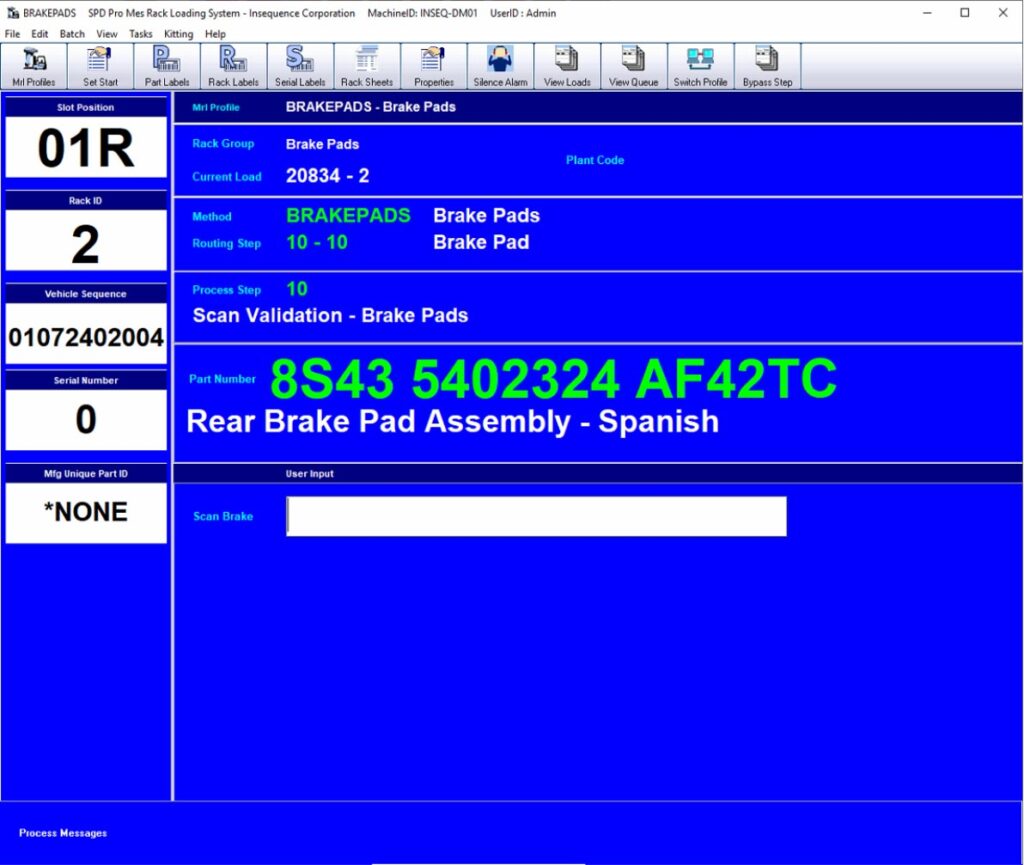

Rack loading

Created primarily for just in sequence, pick/pack, and post-manufacturing, the SPD Pro rack loading application is designed to ensure a smooth and error-proof sequential parts delivery process. Each bar coded commodity is scanned to guarantee sequencing accuracy before a sequence label, tying that part to a specific vehicle, is printed and placed on the part. The part is then loaded onto a rack in the OEM-specified order. Once the rack is complete, SPD Pro automatically prints a rack label or rack sheet.

Rack Audit

With the ability to authorize printing of verification labels, this optional module’s primary function is auditing racks prior to shipment. Additionally, the shipping module can also be configured to check the status of an audit prior to completing shipment.

Shipping

This application is responsible for managing the shipping process of sequenced loads. Moreover, this application not only determines but also error proofs each loading pattern. Once a BOL is posted, this information can then be sent to a suppliers third party system. In addition to communicating with third party systems, Insequence already has interfaces developed for many commonly used ERP systems.

Messenger

This powerful application specifically handles all communication between and within the different SPD Pro applications. Also, almost like a “post office”, Messenger handles communication to other third party systems such as an ERP or WMS.

Application Security

Insequence’s security application allows administrators to set restrictions and levels of access to different SPD Pro modules. Due to this application, the configuration of your software remains secure.

Mobile PCs

Handheld PCs utilizing RDP are fully supported by the SPD Pro sequencing and inventory modules. Additionally for rack loading and shipping, handhelds provide the ability to perform all scans from on mobile device, ultimately running the entire application.

Virtual Machines/Servers

In addition to running on standard servers, SPD Pro has the capability to run on virtual machines/servers as well. Because of Insequence’s versatility, suppliers have more freedom in choosing how to set up their sequencing or manufacturing operations.