Automotive Sequencing 101: What is Automotive Parts Sequencing?

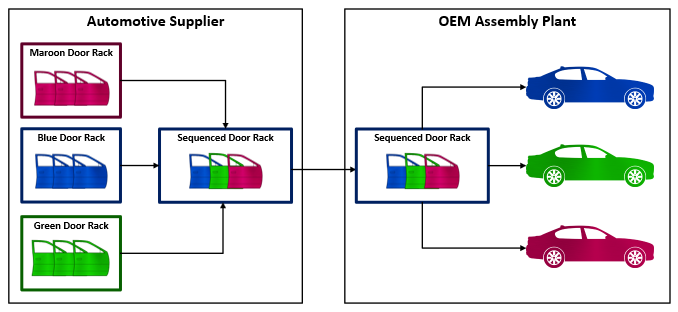

The process of automotive parts sequencing begins with the assembly plant or OEM (Original Equipment Manufacturer) sending part demand to their suppliers in the exact order the parts will be used for building vehicles on the assembly line. Suppliers use this information to sequence and/or manufacture the parts before shipping them to the assembly plant. The parts arrive in the exact order they are needed just in time for installation on that specific vehicle.

Why is automotive sequencing important?

Sequencing is integral to the modern model of automotive manufacturing. It goes a step beyond just in time by eliminating inventory at the OEM plant. This strategy is critical to saving inventory costs along with providing the industry adaptability.

Automotive sequencing improves the process of lean manufacturing. Standing inventory in the automotive industry can be costly. Just the size of certain commodities alone can take up vast amounts of warehouse space that could otherwise be put to more productive use.

By receiving parts in sequence, OEMs no longer have to store all of the variants for each commodity. The same applies to manufacturers shipping in sequence. A single part can have numerous variations depending on what options are available on a vehicle (color, trim level, electronics, etc.). Storing these commodities can take up substantial floor space. Additionally, sequencing promotes lean manufacturing which focuses on reducing waste generated from production. With this process, manufacturers know exactly what needs to be produced, thus reducing wasted material.

The concept of sequencing also provides the industry adaptability. By basing demand off the main assembly line, production does not start until the “recipe” for that vehicle is received. This gives OEMs the ability to alter demand up until it is sent, and sometimes even after. Some OEMs have even adapted their assembly lines to build more than one type of vehicle.

What are the risks?

Automotive sequencing comes with risks. If parts get out of sequence or there is a delay in shipment, it can shut down an assembly plant resulting in lost production and heavy fines from the OEM. This is why reliable sequencing software is so critical to sequential part delivery.

Sequencing software generally includes multiple functions, but the exact operations are dependent on the solution provider. However, most include OEM demand processing, rack loading and validation, label printing, and shipping. Each of these tasks are critical to ensuring smooth and accurate sequential part delivery.

Insequence Corporation

Insequence is a leading provider of sequencing and manufacturing software solutions. Easily tailored to individual facilities, their software’s modular design can fulfill requirements no matter the size or complexity of the system. This results in a standard sequencing system, SPD Pro that is more complete and capable than any other solution. In addition to just-in-sequence (JIS), Insequence provides MES, Inventory Management, and SCADA solutions.

With experience throughout the Americans and Europe, plus over 25 standard automotive OEM interfaces and 24 x 7 x 365 customer support, Insequence is at the forefront of supply chain software solution providers. As a result, they still work with their original customer from 1996.

GO WITH THE PRO.

GO WITH INSEQUENCE.

The Company That Pioneered End-to-End Manufacturing.